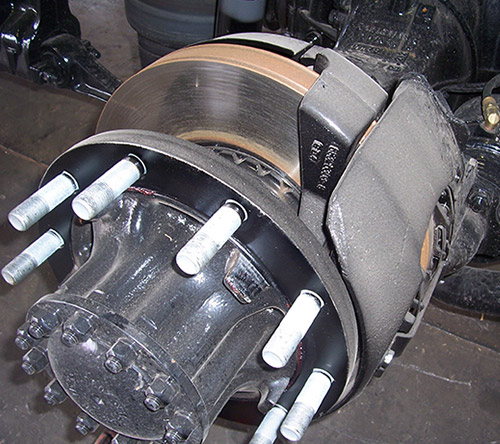

Disc brakes use a hydraulic caliper fitted with brake pads to grab a spinning disc (or rotor). Drum brakes, on the other hand, have a hydraulic wheel cylinder that pushes a brake shoe against the inside of a spinning drum. Either design involves highly engineered parts and precise movement. The more force a driver applies to the brake pedal, the greater the stopping force that is applied at the wheels.

In addition to this primary braking system, most of today’s vehicles utilize an electronic Anti-lock Brake System. Using electronic sensors and high pressure pumps, under certain conditions, your ABS system can measure vehicle speed, wheel slip and brake force. Then it actually pumps the brakes for you during an emergency stop.

That’s why it’s essential to be proactive about testing overall brake components. And to know whether a brake component needs simply to be serviced or totally replaced.

All brake repairs are not created equal. Precision Automotive uses the “Pro-Cut” on the car brake rotor resurfacing machine, the one many auto manufacturers require in their dealerships.